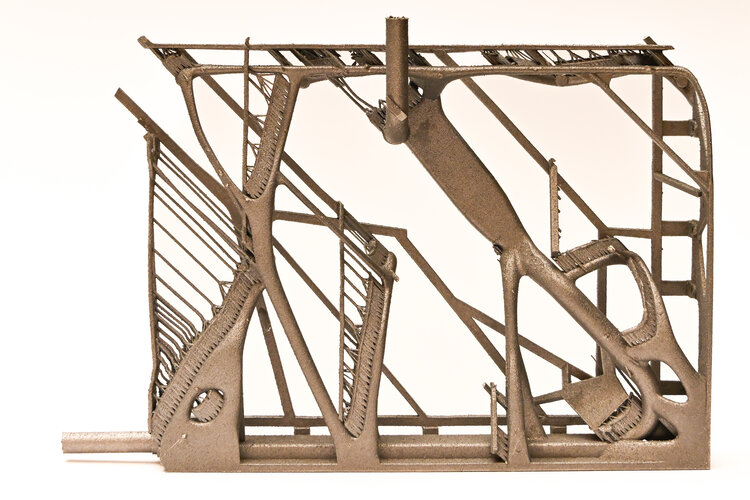

What resembles an abstract artwork is in fact a 3D-printed aluminium frame for a satellite electronics board, designed to help combat one of the major enemies of space missions – heat.

In the weightless vacuum of space, the convection currents that carry away a lot of excess temperature down on Earth do not exist; heat is more likely to stay put.

By slotting an electronics component into this frame, it can be prevented from overheating. The frame does this thanks to ‘heat pipes’ threaded within its structure which carry away waste heat.

Heat pipes work like closed-loop versions of human sweat glands: These pipes contain a liquid – in this case ammonia – that evaporates when heated, carrying waste heat to a colder part of the satellite. At this point the liquid condenses so that the process can repeat itself.

The peculiar organic appearance of the frame comes from a computational design approach called ‘topology optimisation’ that places material just where the loads are, akin to the way a tree grows branches, to take advantage of the extreme versatility of 3D printing.

This cooling frame was designed and produced for ESA by a consortium led by EHP in Belgium, through the research project ‘Assessing the use of Advanced Manufacturing to improve and expand space hardware capabilities’ supported by the Agency’s General Support Technology Programme, backing promising new technologies and products for space.

Image:

Cool by design 3D printing

Image:

Cool by design 3D printing