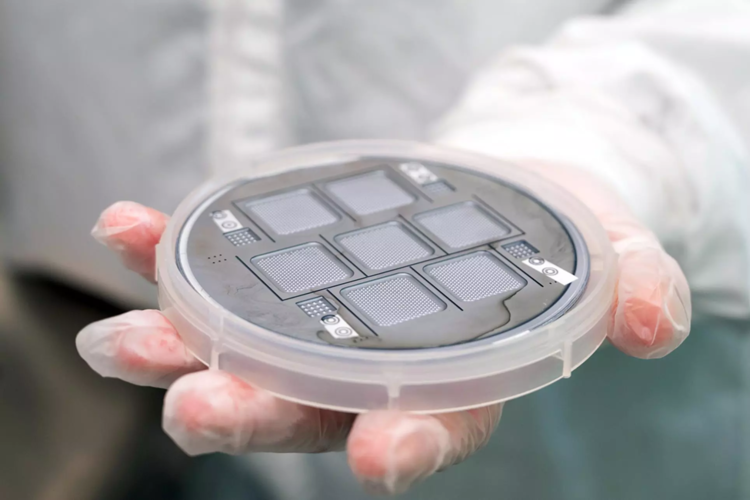

A palm-sized propulsion option for future space missions: each one of these seven emitter arrays etched onto this silicon wafer using micro- and nano-technology possesses more than 500 pinhole-sized emitters that spray out ions, accelerated via an electrostatic field to maximise thrust.

Inherently scalable, this ‘electrospray’ technology is being developed as a cost- and mass-effective method of propelling CubeSats and other small satellites. For the first time in Europe, this ionic-liquid based electrospray propulsion system has achieved more than 400 hours of continuous operation.

“Everyone knows that ‘space is hard’, but we like to say that ‘propulsion is harder’,” comments Daniel Pérez Grande, CEO & Co-founder of IENAI Space in Spain, developing the technology for ESA. “Developing a new technology, which we have built from scratch, has been no easy feat, but we are confident that our propulsion products will stand out in the market for their incredible performance and customisation capabilities; and in fact we have already been approached by a number of interested parties in the industry.”

Known as ATHENA (Adaptable THruster based on Electrospray powered by Nanotechnology), this system is one of three currently being developed by ESA to harness electrospray propulsion for space. ATHENA relies on conductive ionic-liquid salts as a fuel. This liquid flows through nano-textured conical emitters to be accelerated between an emitter and an extractor operating at different electric potentials. The interaction between the surface tension of the liquid and the applied electrostatic field forms ions which can be sprayed out at very high speeds (on the order of 20km/s), creating the force to move the satellite.

The micro-fabricated ATHENA system has the advantage of highly customisable thrust, using non-toxic ‘green’ propellants with no need for pressurised tanks. And the thrusters can be clustered together freely as needed – a total of six would fit onto the 10 cm face of a single CubeSat unit. These units can then be further clustered to deliver thrust for satellites of up to 50kg in mass.

The project has now passed its Preliminary Design Review, targeting a final product by the end of next year. Development has been supported through ESA’s General Support Technology Programme, readying innovative products and services for spaceflight and the open market.

Image:

Pinhole propulsion for satellites

Image:

Pinhole propulsion for satellites