Biomanufacturing based in space can improve the sustainability of deep space exploration. Bioprocessing systems to advance biomanufacturing for space applications need to be developed. In a new report now published in npj Microgravity, Mathangi Soundararajan and a team of scientists in bioengineering and space biosciences at the NASA Ames Research Center, California, have developed commercial technologies to design space bioprocessing systems that supply a liquid amine carbon dioxide scrubber with recombinant active carbonic anhydrase. The design workflows encompassed a biomass of 1 L of Escherichia coli cultures using recombinant protein purification.

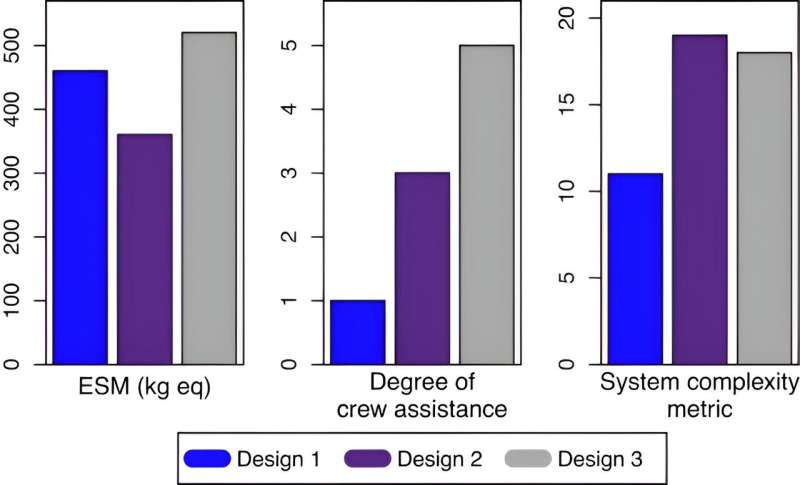

The team described three designs that differed in biomass dewatering and protein purification approaches. Values from system complexity metric, technology readiness level, and integration readiness level identified a bioprocessing system design that minimized complexity and enabled versatility.

Carbon capture technology for space missions

Liquid amine scrubbing provides a mature post-combination carbon capture technology on Earth as a promising approach to scrub CO2 produced during crewed space missions. The thermal amine scrubber on the International Space Station provides one of the three candidate methods to remove CO2 and function in space. In its mechanisms of action, cabin air with elevated levels of CO2 is passed across an organic liquid amine, which is absorbed the carbamate or bicarbonate, depending on the solvent.

Long duration space missions close to Earth require a time-course supply of carbonic anhydrase that can be met through resupply and long-term storage. This option isn't viable for Mars space missions, however. While space biomanufacturing systems can produce enzymes and other biological materials during Mars space missions, space systems must minimize the costs including crew time, while facilitating astronaut safety to address the effects of increased radiation and reduced gravity.

Biomanufacturing methods in space

Research on preceding space biomanufacturing methods have focused on large-scale mission design and microbial growth kinetics, as well as bioreactor designs. In this new work, Soundararajan and the team compared commercial methods and potential designs for in-space biomanufacturing.

The team developed an operational scenario for post growth bioprocessing to produce recombinant carbonic anhydrase from E. coli during a Mars mission. The team qualitatively compared multiple variables and crew-assisted steps to guide future prototype development efforts.

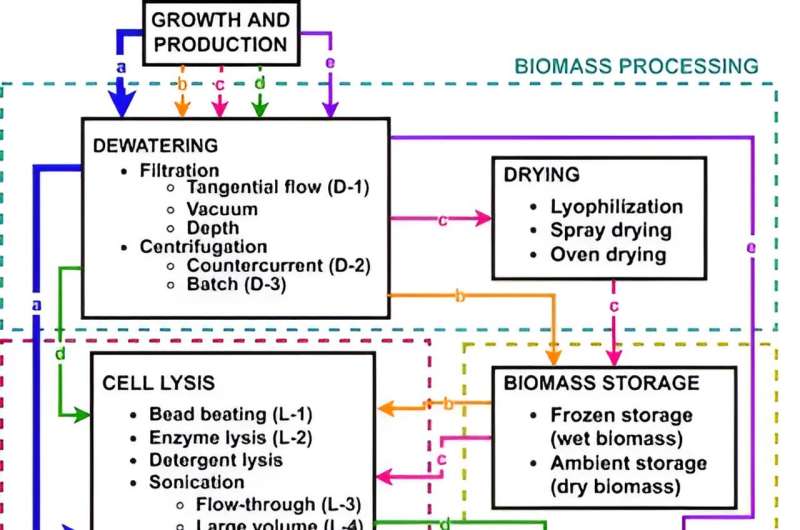

The team examined five potential bioprocessing workflows starting from common cell growth and production. Each workflow included subprocesses of biomass processing, protein extraction and storage. They subdivided the biomass processing to dewatering and drying steps as primary options.

The methods allowed the production of intracellular recombinant proteins and required a protein extraction subprocess, which included cell lysis, protein purification and buffer exchange or desalting for the final protein product to be stored as a biomass or a purified product. Soundararajan and colleagues supplied purified carbonic anhydrase on a six-to-eight-day cycle to produce recombinant proteins in terrestrial applications.

Biomass processing and protein extraction

Since dewatering cultures greatly reduced processing volumes for protein extraction or biomass storage sub-processes, scientists could also complete protein extraction without a dewatering step. The team observed the impact of dewatering on cell lysis and protein purification in the project. The dewatering step facilitated flow-through methods as options in bioprocessing designs. The equivalent system mass analysis models for lysis removed the process of sonication due to experimental necessities of high power and cooling. During the protein purification experiments, the team compared five commercial affinity purification methods.

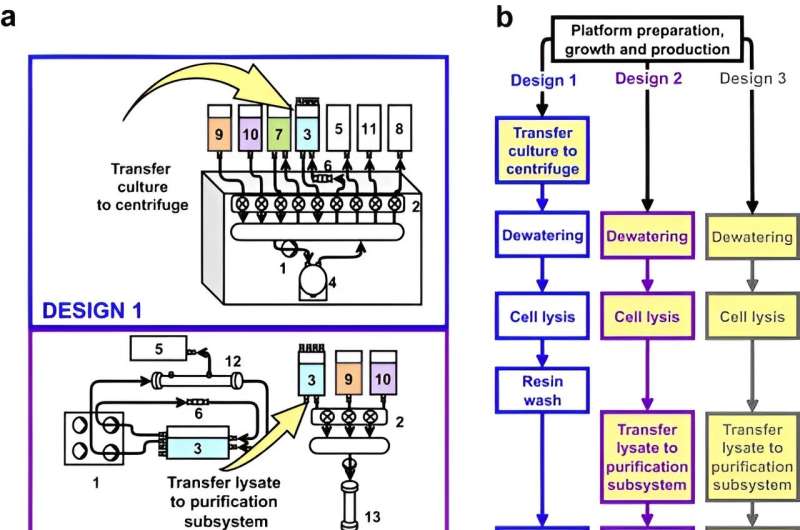

They then developed bioprocessing system integrated designs with the resource and risk-reduction rationale to select specific steps and methods. They reduced the methods of biomass storage, product storage and drying steps. The team used a counterflow centrifugation system to dewater biomass, lyse cells and purify the protein with a batch resin method in which they mediated material flow by a peristaltic pump to ultimately transfer lysate into an affinity resin reservoir for protein binding. The research team eluted the bound protein from the resin for centrifugal separation and collection in a production reservoir. They then designed two other variants of bioprocesses for peristalsis, dewatering and lysis and compared the units for optimal functionality.

Comparative analysis of designs

Each design integrated different methods to accomplish the same bioprocessing outcome. The system complexity metric estimated the complexity of life support systems by adding the components and proposed interconnections of a specific design to compare CO2 removal systems.

The larger metrics were more applicable to more complex systems. The team included major components and interconnections to calculate the system complexity for three designs. The three designs each contained two subsystem interfaces—a dewatering lysis and lysis-protein purification.

Outlook

In this way, Soundararajan and colleagues improved the efficiency of liquid amine CO2 capture systems by using carbonic anhydrase—a candidate technology for deep space missions. The enzyme-assisted liquid amine system required a steady supply of carbonic anhydrase for long-term storage with low temperature storage conditions.

During the study, the team investigated multiple approaches to rank the technologies used to design integrated systems intended for space missions. The NASA Space Synthetic Biology project is based on the development of a prototype bioprocessing system. The ongoing workflow is expected to identify and integrate methods for efficient translation and improved efficiency for industrial biomanufacturing efforts on Earth too.

More information: Mathangi Soundararajan et al, Theoretical design of a space bioprocessing system to produce recombinant proteins, npj Microgravity (2023). DOI: 10.1038/s41526-023-00324-w

Journal information:npj Microgravity

© 2023 Science X Network