Carbon-plastic fantastic

ESA’s Phoebus project is looking to carbon fibre-reinforced plastic for the next generation of rocket fuel tanks. Carbon fibre materials have taken the world by storm as they are extremely lightweight and strong, but so far they have not been able to be made suitably leak-tight for storing liquid hydrogen, nor liquid oxygen due to its reactivity. European teams at ESA, MT Aerospace and ArianeGroup have now overcome both these limitations by using new manufacturing technologies, as well as state-of-the art design methodologies and fine-tuning the plastics chemistry.

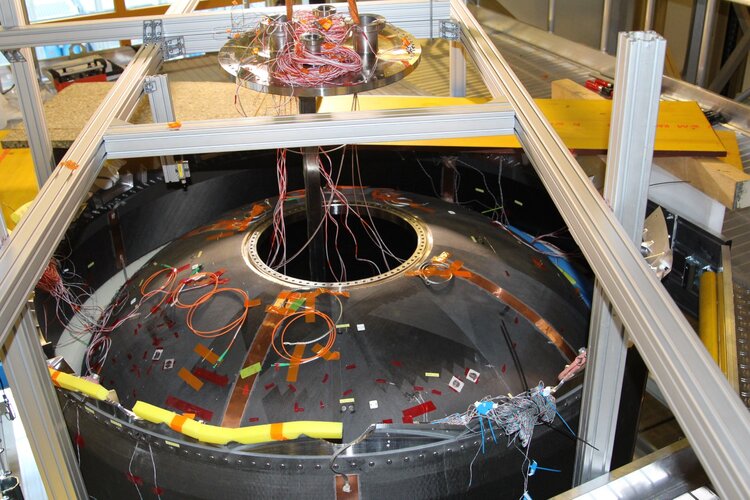

Phoebus is a carbon-fibre reinforced-plastic fuel tank demonstrator that is built from the ground up using layer-by-layer manufacturing. This technique and the innovative design allow engineers to construct a unique shape that suspends the fuel tank inside a supporting frame, with an insulating air gap in between, solving many of the problems above in one additive swoop. Light-weight, strong, leak-tight and non-reactive, last week a key element of the Phoebus project passed its test-readiness review and was given the go-ahead to proceed for testing, where a 2-m-diameter model oxygen tank will be tested as if it were really flying. A similar scale hydrogen tank will be tested next year, ahead of the testing of a full-scale structural demonstrator of a complete upper stage in 2025.

“The physics, chemistry and construction techniques behind this project are mind-boggling,” says Kate Underhill, ESA’s lead engineer on the project. “When we started Phoebus, the risks were high and the fact that the project has reached this stage is thanks to the huge commitment and know-how of teams involved at ESA, MT Aerospace and ArianeGroup working together as one.”