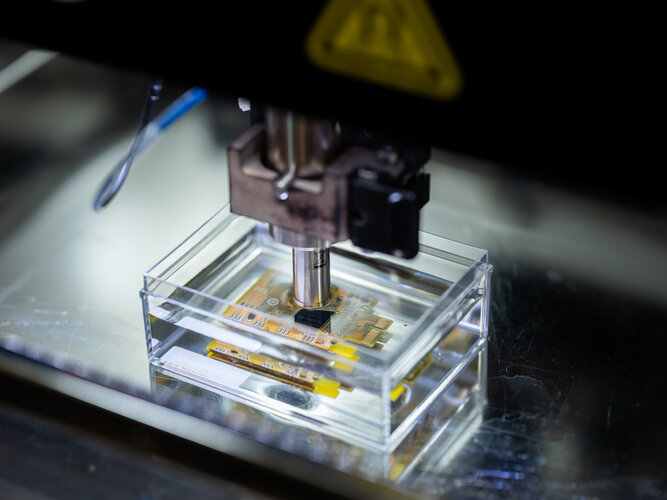

How does ESA tell if candidate components for future missions have the right stuff for space? First they undergo rigorous ‘environmental testing’ – such as sustained exposure to vacuum, temperature extremes or vibration. Then the resulting condition of a test item is assessed with powerful analytical tools, such as this acoustic microscope.

Part of ESA’s Materials and Electrical Components Laboratory, which is one of a suite of technical labs based at the ESTEC centre in the Netherlands, the acoustic microscope sends out ultrasound pulses whose echoes can highlight cracks and other anomalies in candidate parts down to the scale of micrometres, or thousandths of a millimetre.

The lab is additionally equipped with various optical, scanning electron and confocal microscopes, including a scanning probe microscope offering resolution right down to the atomic scale.

Made up of more than 20 dedicated experimental facilities and hundreds of instruments overall, the Materials & Electrical Components Laboratory guarantees an optimal choice of electrical components, materials and processes for ESA missions and external projects.

Image:

Acoustic inspection

Image:

Acoustic inspection