It doesn't actually use high-tech digitized thread to create spacesuits. Instead, it utilizes the Digital Thread framework commonly used in the industrial Internet of Things settings. The best way to describe the Digital Thread is to think of it as a piece of data that connects an individual part through all the design, manufacturing, and delivery processes.

Get enough of these pieces of data to describe an individual object, and you end up with what is called a digital twin—a representation of the object in a digital space. Digital twins can then reproduce the object ad infinitium if necessary. But they can also be used to tweak and individualize the item based on the inputs on specific characteristics.

That seems to be the path that Dr. Dunbar and her team are going down. While she was an astronaut, Dr. Dunbar noticed a significant shortfall of spacesuits for the astronaut core during the shuttle period—only 18 suits were manufactured for 200 astronauts. Not all of the astronauts could fit in those suits, and many suffered from problems using them, including lost fingernails and a significant loss of strength. What's more—many are still in use today, over 40 years after they were initially designed.

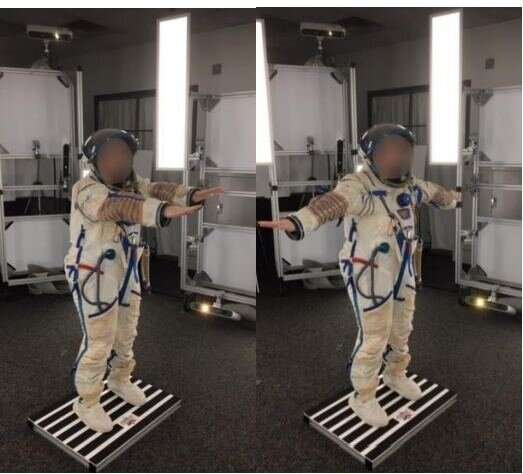

Motion capture of a subject in an old Russian spacesuit. Credit: Hall et al. & Art Dula

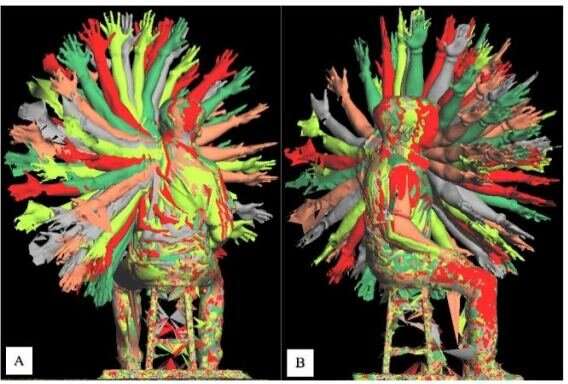

Screenshot of the range of motion image captures completed as part of the digital twin modeling. Credit: Hall et al.

But there is an alternative—during the Apollo era, each space suit was explicitly tailored to the individual for whom it was intended. They had no such problems, with Apollo 17 astronauts saying they were happy with how their suits functioned. The problem is that there weren't too many Apollo astronauts; now, hundreds of people, including civilian tourists, are planning to go to space. It would be prohibitively expensive to fit them all with custom suits, even with the exorbitant price tags some space tourists are willing to pay for their flight to orbit.

Enter Dr. Dunbar's "digital thread" idea. Creating a digital twin of a generic space suit would allow designers to take measurements specific to a user and alter that digital twin to create a custom-fitted suit without the massive expense of creating one from scratch. To that end, Dr. Dunbar's previous research focused on finding the metrics that would be necessary to customize a spacesuit. Her research lab used a full 3D body scanner to create a complete digital twin of an individual, including their range of motion. That information could then be applied to the digital twin of the spacesuit, allowing quick customization.

Having a specially designed digital twin is excellent, but spacesuits aren't useful unless they are physical objects. So what would be the process of actually making one of these tailored suits? That seems beyond the scope of this Phase I grant, though the proposal hints that in situ repairs and fabrication of parts could be in the offing. Most likely, that would require a type of 3D printer, particularly one that could recycle previously made spacesuit parts. No such technology exists—yet. Maybe, if Dr. Dunbar's research is successful, it could crop up in the next round of NIAC funding.

Explore further