To address this issue, researchers in Harbin Institute of Technology's School of Mechanical Engineering and Automation have developed a robotic arm weighing 9.23 kilograms—about the size of a one-year-old baby—capable of carrying almost a quarter of its own weight, with the ability to adjust its position and speed in real time based on its environment.

They published their results on Sept. 28 in Space: Science & Technology.

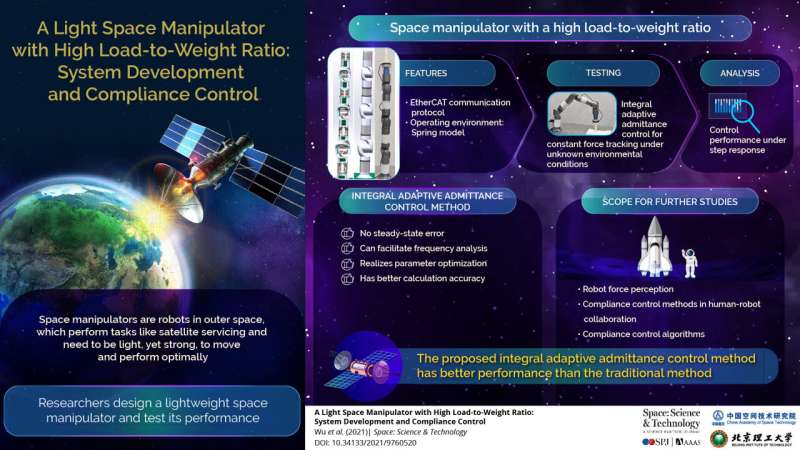

"In order to solve the problems of strict restrictions on the mass and size of the manipulator, as well as the high requirements for reliability and safety of the control method in space operation, we developed a light space manipulator and proposed a new control method," said corresponding author Wenfu Xu, professor in Harbin Institute of Technology's School of Mechanical Engineering and Automation and State Key Laboratory of Robotics and System.

Such a manipulator needs to exert constant force control when in operation.

"For the constant force control of a plane, the direction of control force is constant, but for a curved surface in an unknown environment, its normal vector is often changed in real time, so the traditional method would fail," Xu said. "In order to overcome this difficulty, we propose integral adaptive admittance control that can realize real-time correction of the desired position of the end of the manipulator so that it is in full contact and realizes constant force control."

Compare it to a drawing a line on a piece of paper. When the paper is on a flat desktop, it's much easier to maintain even pressure across the line. Drawing an identical line on a sheet of paper wrapped around a bouncing ball is much more difficult and requires specific calculations to understand the movement of the ball and how much pressure to exert based on the position of both the pen and the ball.

To keep the force control of the space manipulator constant, the researchers imposed a control method that removes the need for steady-state correction—a key component of control systems in known environments. Steady-state correction applies the potential error to the full movement, which eases problems when the environment is predictable. For example, if the manipulator knows the desk's surface is rough and strong pressure would cause the paper to rip, it can lighten the pressure of the pen to maintain a constant line. But when the surface is changing and unpredictable, maintaining a constant corrective state results in more errors, since not all corrections apply to all errors.

The researchers tested their control method for the lightweight manipulator and found that, even on an unknown surface, the mechanical arm could adjuster quicker than a traditionally controlled manipulator, resulting in a tracking effect steady enough for practical applications.

"Using the proposed light space manipulator and the integral adaptive admittance control method can solve practical problems on on-orbit servicing, such as space target capturing, on-orbital assemble, orbital repairing and so on," Xu said.

According to Xu, this work can serve as a reference for the design of light manipulators in the future, while the control approach can be applied to the machining process of robotic surface grinders and polishers.