Displaying items by tag: ion propulsion

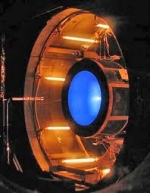

NEXT (thruster)

NEXT, the NASA Evolutionary Xenon Thruster project at Glenn Research Center aims to build an ion thruster about three times as powerful as the NSTAR used on Dawn and Deep Space 1.

By 2008, flight qualification models of the thruster were available. NEXT has 6.9 kW thruster power and 236 mN thrust, can be throttled down to 0.5 kW power, and has an ISP of 4190 seconds (compared to 3120 for NSTAR). The thrusters are manufactured at Aerojet and the power-management units at the ETI division of L3 Communications.

Dual-Stage 4-Grid (DS4G) thruster

The Dual-Stage 4-Grid (DS4G) is an electrostatic ion thruster design developed by the European Space Agency, in collaboration with the Australian National University.

The design was derived from Controlled Thermonuclear Reactor experiments that use a 4-grid mechanism to accelerate ion beams.

Aerojet

[ merged in 2013 in Aerojet Rocketdyne ]

Aerojet was an American rocket and missile propulsion manufacturer based primarily in Rancho Cordova, California, with divisions in Redmond, Washington, Orange, Gainesville (both in Virginia) and Camden, Arkansas.

Aerojet was owned by GenCorp. It was one of the rare companies that provide both solid rocket motors and liquid rocket engines. Its products include a range of motors, from main engines used on a number of NASA vehicles and ballistic missiles, down to station-keeping thrusters for spacecraft. The propulsion devices include rocket motors as large as the EELV Atlas V strap-on rocket boosters.

Aerojet provided almost all of the USA Army's tactical missile rocket motors. They develop and manufacture a range of air breathing ramjet and scramjet engines. They also do research in the area of electric ion and Hall effect thrusters.

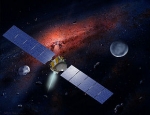

Dawn (spacecraft)

Dawn is a robotic NASA spacecraft tasked with the exploration and study of Vesta and Ceres, the two largest members of the asteroid belt.

Launched on September 27, 2007, the probe entered orbit around Vesta on July 16, 2011.

Dawn left Vesta on September 5, 2012, on a course for Ceres, which it is scheduled to reach in February 2015.

Managed by NASA's Jet Propulsion Laboratory, Dawn is NASA’s first purely exploratory mission to use ion propulsion. The spacecraft was constructed with some European cooperation, with components contributed by partners in Germany, Italy, and the Netherlands. Dawn was the first spacecraft to visit Vesta, and is scheduled to be the first to visit Ceres. If it successfully reaches Ceres, it will also be the first spacecraft to orbit two separate extra terrestrial bodies, using ion thrusters to travel between its targets. Previous multi-target missions using conventional drives, such as the Voyager program, were restricted to flybys.

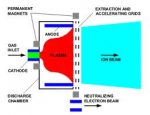

XIPS - Xenon Ion Propulsion System

XIPS is a com-mercial electron bom-bardment thruster (also known as an electrostatic ion thruster) – a form ion propulsion – that is a product of Hughes Space and Communications Company, which, in 2000, became part of Boeing Satellite Systems.

XIPS (pronounced "zips") employs the heavy inert gas xenon as a propellant. It was first used operationally aboard the PAS-5 (PanAmSat-5) communications satellite in 1997 and has since been fitted to many other geosynchronous satellites for use primarily in station-keeping. In a XIPS, xenon atoms are injected into an ionization chamber and ionized by electron bombardment. The propellant is then electrostatically accelerated through a series of biased grids. Ions, ejected by XIPS, travel in a stream at a speed of 30 km/s (62,900 mph), nearly 10 times that of a conventional chemical thruster. The high efficiency of the system leads to a reduction in propellant mass of up to 90% for a satellite designed for 12–15 years operation.

For example on a XIPS equipped Boeing 702 satellite, four 25-cm thrusters provide economical station keeping, needing only 5 kg of fuel per year. Boeing asserts that this is "a fraction of what bipropellant or arcjet systems consume". Boeing further asserts, that a XIPS can be used for final orbit insertion and has orders ( source: Wikipedia, Boeing_702 ) for spacecraft utilizing only ion thrusters. This conserves even more payload mass, as compared to using an on-board liquid apogee engine.

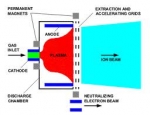

XIPS - Xenon Ion Propulsion System

XIPS is a commercial electron bombardment thruster (also known as an electrostatic ion thruster) – a form ion propulsion – that is a product of Hughes Space and Communications Company, which, in 2000, became part of Boeing Satellite Systems.

XIPS (pronounced "zips") employs the heavy inert gas xenon as a propellant. It was first used operationally aboard the PAS-5 (PanAmSat-5) communications satellite in 1997 and has since been fitted to many other geosynchronous satellites for use primarily in station-keeping. In a XIPS, xenon atoms are injected into an ionization chamber and ionized by electron bombardment. The propellant is then electrostatically accelerated through a series of biased grids. Ions, ejected by XIPS, travel in a stream at a speed of 30 km/s (62,900 mph), nearly 10 times that of a conventional chemical thruster. The high efficiency of the system leads to a reduction in propellant mass of up to 90% for a satellite designed for 12–15 years operation.

For example on a XIPS equipped Boeing 702 satellite, four 25-cm thrusters provide economical station keeping, needing only 5 kg of fuel per year. Boeing asserts that this is "a fraction of what bipropellant or arcjet systems consume". Boeing further asserts, that a XIPS can be used for final orbit insertion and has orders( source: Wikipedia, Boeing_702 ) for spacecraft utilizing only ion thrusters. This conserves even more payload mass, as compared to using an on-board liquid apogee engine.